A quick return mechanism is an system to produce a resiprocating effect such that time taken by system in return stroke is less time taken by it in the forward stroke.

In quick return mechanism, a circular motion is converted into reciprocating motion just like crank and lever mechanism but it has return stroke time is different from forward stroke time.

This mechanism is used in many machines. Some of them are shaper machines, slotter machines, screw press, mechanical actuator etc.

With the help of quick return mechanism, the time needed to cutting is minimized.

- Quick Return Mechanism In Slotting Machines

- Slotting Machine Tools

- Slotting Attachment For Milling Machines

- Cnc Slotting Machine

Types of Quick Return Mechanism:-

1 Hydraulic Drive:

Hydraulic drive mechanism is one of the mechanism used in shaper machine. In this mechanism, the ram is moved forward and backward by a piston moving in a cylinder placed under the ram.

This machine consists of a constant discharge oil pump, a cylinder , a valve chamber and a piston. The piston ram is bolted to the the ram body.

Hydraulic fluid is used in hydraulic quick return mechanism for the movement of ram.

Draw an alternative mechanism or combination of mechanisms that will produce the same forwards and backwards motion. Is your new mechanism an improvement on the crank and slider mechanism? Draw a diagram of the shaping machine and explain how the quick return mechanism works. A quick return mechanism is a mechanism which produces a reciprocal effect so that the system takes less time in the return stroke while comparing with forward stroke. In the quick-return mechanism, a circular movement like the crank and lever mechanism is converted into reciprocal movement but the return time is different from the forward moment.

Quick Return Mechanism In Slotting Machines

Working of Hydraulic Drive :-

In hydraulic drive, there is a tank at the bottom which contains the hydraulic fluid. This tank is also known as oil reservoir.

At first the oil from the reservoir.

This oil is passed through the valve chamber present in the right of the oil cylinder exerting pressure on the piston.

Any oil present in the left side of the piston is discharged to the reservoir through the throttle valve.

At first the fluid in the tank is pumped out and this fluid passes through the passage present in the right side of the cylinder .

This fluid exerts pressure on the piston and the ram of the machine performs forward stroke.

When the ram moves forward, the lever changes its position and hits the reversing dog. As the lever changes its position, the three valves connected to the lever also change their position and now the oil can pass through the passage present in the left side of the cylinder.

After the forward stroke is completed, the valves changes its position and now the pumped fluid from the reservoir moves from the passage present in the left side of the piston. Also, the passage through which the oil return to the reservoir opens and get connected to the right passage and the fluid present on the right side of the piston is discharge to the reservoir.

As the fluid moves towards the left side of the piston, the piston which is attached to the ram moves towards right and return stroke is performed by the ram.

At the end of the return stroke, another dog hit against the lever and the direction of the lever as well as the stroke changes. In this way, the forward and the return stroke of the ram is repeated.

The quick return takes place due to difference in the stroke volume of cylinder at both ends. The volume of passage at the left side is less than the volume of the passage on the right side. As the pump is constant discharge pump, same amount of oil will be passed on the both passage. So the pressure n the passage with less volume will be more and the return stroke will be faster than the forward stroke.

The cutting speed can be controlled by controlling the flow of oil which can be controlled by using the throttle valve.

When the throttle valve is lost the excess valve is cut through the relief valve to the reservoir maintaining uniform pressure during the cutting stroke.

2. Whitworth Quick Return mechanism :-

This mechanism changes the rotary motion to oscillatory motion like the crank and lever mechanism.

The difference between the crank and lever mechanism and Whitworth mechanism is that in whitworth mechanism the return stroke is faster than the forward stroke while in the crank and lever mechanism the forward stroke is of same speed as that of return stroke.

Parts used in Whitworth mechanism :-

1) Slotted Bar.

2) Slider

3) Crank – It will rotate.

Whitworth quick return mechansim is the second inversion of slider crank mechanism in which the crank is fixed.

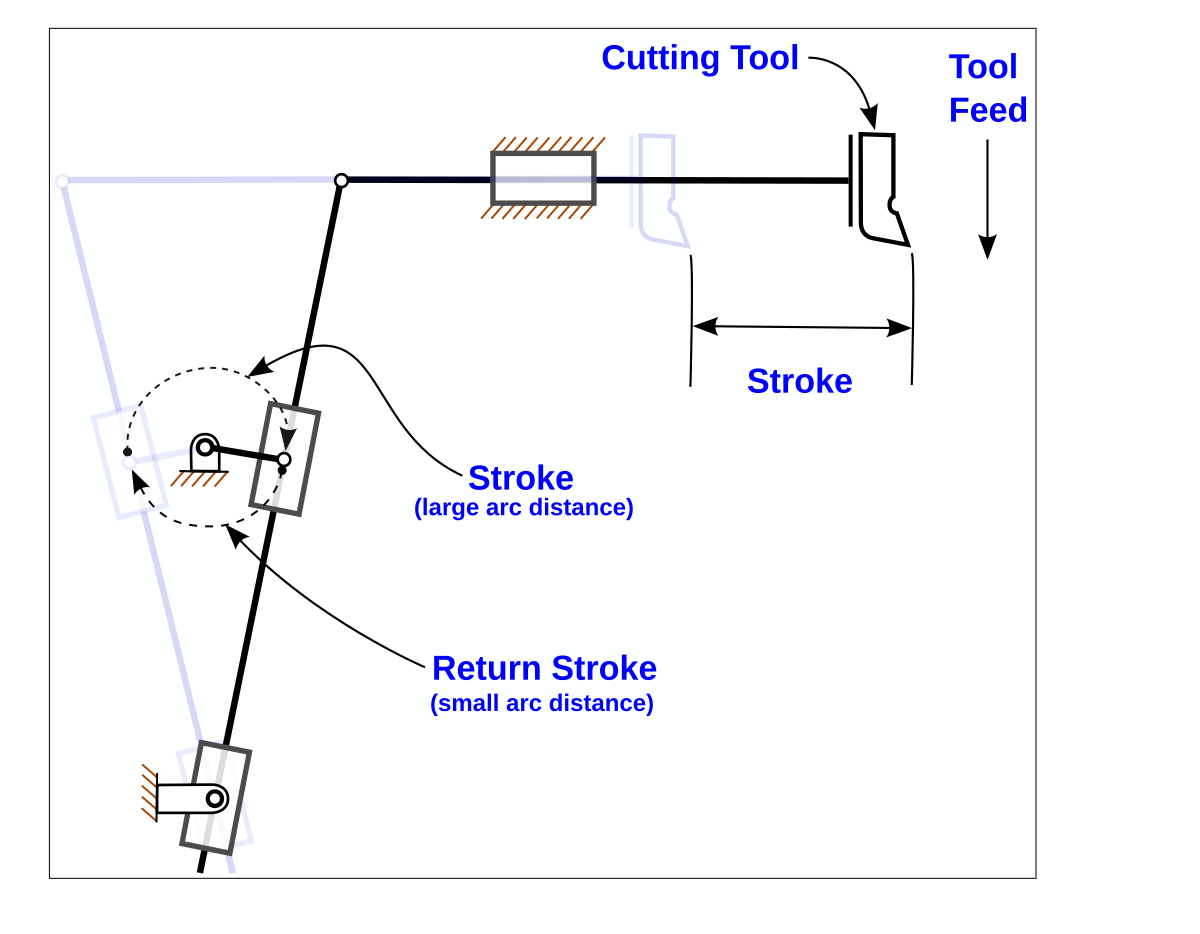

In this mechanism, the Slider in slotted bar is connected to the crank. When the crank rotates, the slider will slide inside the slotter bar and the slotted bar will oscillate. As the slotted bar oscillate, the ram will move in forward and backward direction.

The return stroke or ideal is faster than the forward stroke in this mechanism.

Slotting Machine Tools

In the above figure AP is the slotted bar and link 1, CD is link 2, AC which is crank is link 3 and link 4 is the slider.

In this mechanism the link CD i.e link 2 forming the turning pair is fixed as shown in the figure above.

The crank AC revolves with uniform velocity with its centre at A.

A sliding block attached to the crank pin at B slides along the slotted bar AP and thus causes Ap to oscillate about the pivoted pint A. A short link PR transmits the motion from AP to the ram which carries the tool and thus forward stroke and backward stroke is obtained.

The crank needs to rotate through an angle of ( β ) for the forward stroke and it needs to rotate through an angle of ( α ) for forward stroke.

As crank moves with uniform angular velocity , time taken to cover angle α will be less than the time taken to cover angle β. Hence time taken in return stroke will be less than time taken in forwaed stroke. In this way, the quick return mechanism works.

3) Crank and Slotted Link Mechanism:-

In crank and slotted link mechanism. The power is transmitted to the bull gear by a pinion which recieves its power from an individual motor.

In a two gear system, the smaller gear is called pinion and the larger gear is called bull gear.

Working of Crank and Slotted Link Mechanism:-

The radial slide is bolted to the centre of the bull gear. This radial slide carries a sliding block into which the crank pin is fitted.

As the bull gear will rotate, the crank will revolve at uniform speed.

The sliding block which is mounted upon the crank pin is fitted upon the crank pin is fitted within the slotted link. This slotted link is pivoted uponat its bottom end attached to the frame of column. The upper end of the sliding link is bifurcated and attached to the ram block by a pin.

When the bull gear rotates, the crank pin revolves at a uniform speed. The sliding block fastened to the crank pin will rotate on the crank pin circle and at the same time this slider will slide up and down in the sliding link.

As the slider will move inside the sliding link, it will provide a rocking movement to the sliding link and this movement will be transferred to the ram providing it a resiprocatory motion.

Hence the rotary motion of the bull gear is converted into resiprocatory motion of ram.

ABSTRACT:

The goal of this analysis is to research the kinematics movement of a Crank and Slotted Lever Quick Return instrument. The examination is to demonstrate that it is, in fact, a snappy return instrument and to assess the expansion in proficiency this would offer if connected to a mechanical device.

PRESENTATION:

Meaning of a Mechanism

A system is a disentangled model, for the most part as a line graph, which is utilized to imitate the movement happening in a machine. The reason for this multiplication is to empower the idea of the machine. The reason for this multiplication is to empower the idea of the movement to be researched without the encumbrance of the different strong bodies which shape the machine components The different parts of the system are called connections or components. Where two connections are in

Slotting Attachment For Milling Machines

contact and a relative movement is conceivable, at that point they are known as a couple. A discretionary arrangement of connections which shape a shut chain that is equipped for relative movement, and that can be made into an unbending structure by the expansion of a solitary connection, is known as a kinematic chain. To shape a component from a kinematics chain one of the connections must be settled. Anyway as any of the connections can be settled, it takes after that there is the same number of the system as there are interfaces in the chain. The method of getting distinctive instrument by settling the different connections thusly is known as the reversal.

WORKING PRINCIPLE:

Kinematics Pairs

The relative movement between two connections of a couple can take the diverse frame. Three sorts of a sets are known as lower sets and these are the oftentimes happening ones: Sliding, for example, happens between a cylinder and a barrel Turning, for example, happens with a wheel on a pivot Screw movement, for example, happens between a nut and a fastener All different cases are thought to be mixes of sliding and rolling are called higher sets. Entirely screw movement is a higher match as it joins turning and sliding. Slider – Crank Mechanism The slider-wrench component is outstanding as the premise of a responding motor. As appeared in the outline beneath it comprises three turning sets and one sliding pair

In the above outline, the connection 1 is settled. On the off chance that we presently settle interface 2, that is thinking about a reversal of the component, we acquire the instrument demonstrated as follows. This is known as Whitworth’s Quick Return Mechanism.

Cnc Slotting Machine

DOWNLOAD: QUICK RETURN MECHANISM BY USING CRANK AND SLOTTED LINK MECHANISM——6000